Introduction:

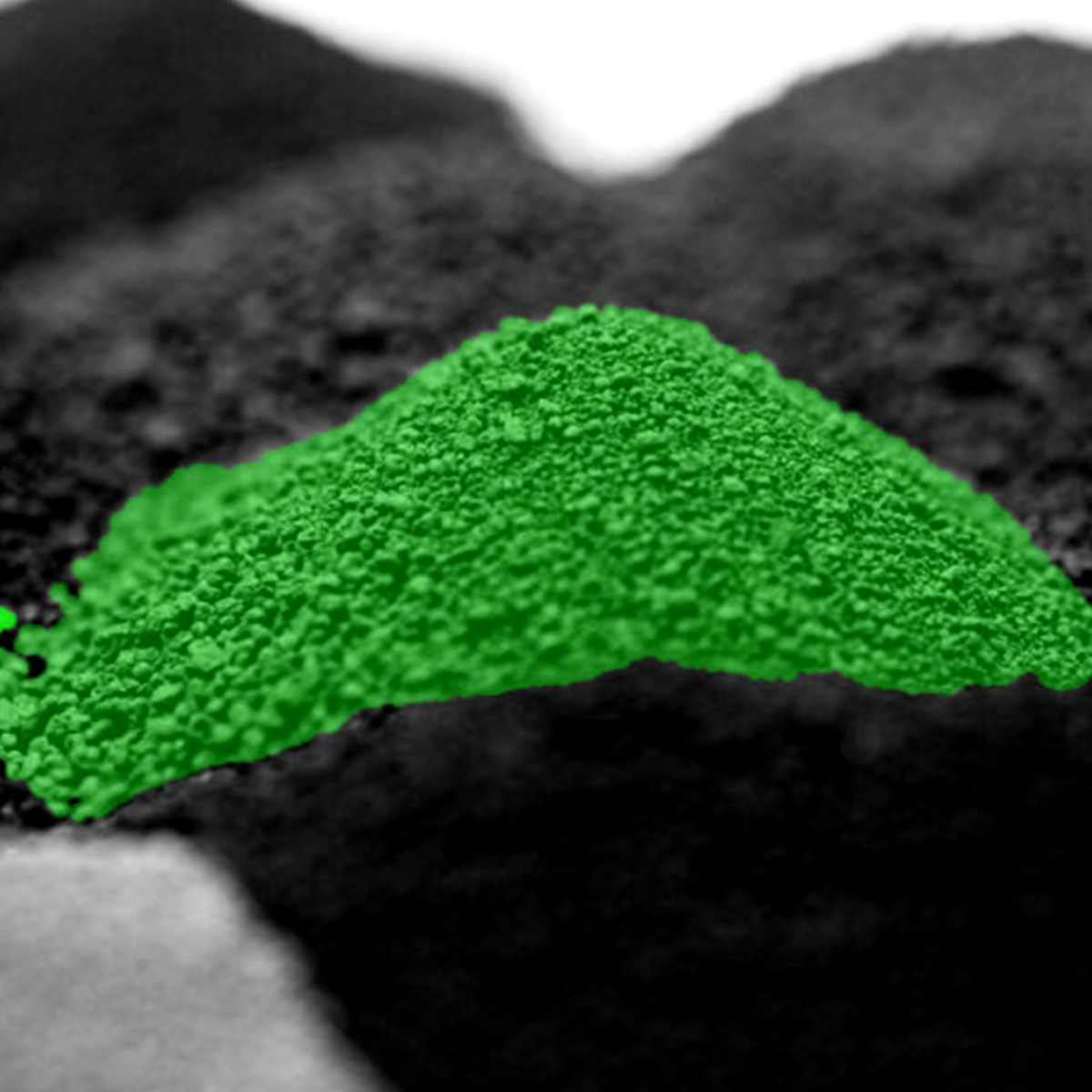

Recycled precipitated silica refers to the process of reclaiming or reusing precipitated silica that has been obtained from various sources and subjected to a recycling procedure. Precipitated silica is a form of silica that is synthetically produced by precipitating silicon compounds from a solution.

- K160: Highly dispersed silica has high purity, low metal impurities and good index stability. Green tires, special rubber parts, etc. And it has reinforcing properties, microbead material, easy to mix and automatic metering.

- K195: Highly dispersed silica has high purity, low metal impurities and good index stability. And it has reinforcing properties, microbead material, easy to mix and automatic metering.

- K2000: Highly dispersed and high specific surface area silica has high purity, low metal impurities, and good index stability, exclusively for green tires. And it has reinforcing properties, microbead material, easy to mix and automatic metering.

Specification:

| ITEM | K160 | K195 | K2000 |

|---|---|---|---|

| BET | 140-180 | 155-195 | 190-230 |

| PH | 6.0-7.5 | 6.0-7.5 | 6.0-7.5 |

| Moisture | 4-8% | 4-8% | 4-8% |

| SiO2 | ≥90% | ≥90% | ≥90% |

Application:

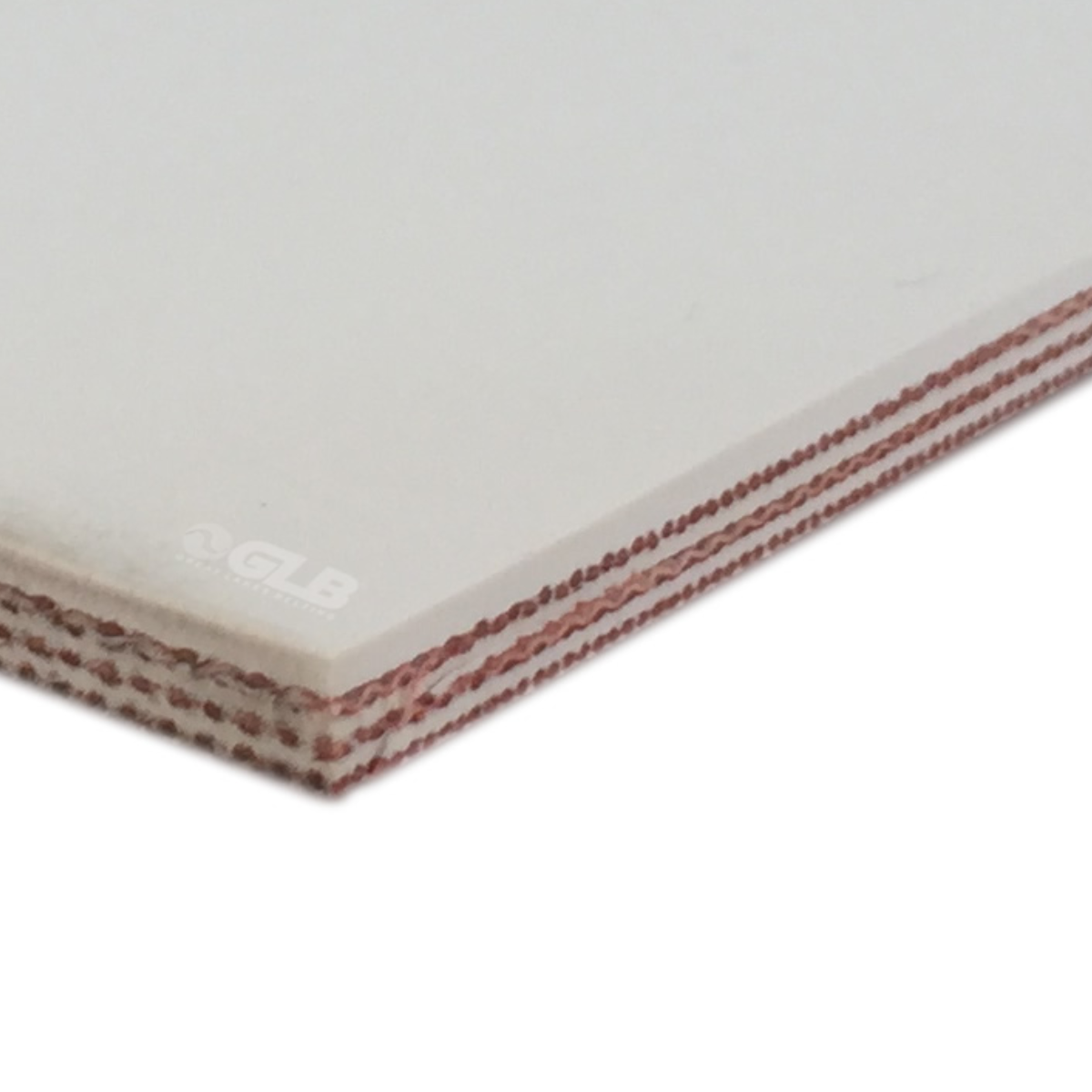

Recycled precipitated silica is often used as a reinforcing filler in tire production, and it can be used in various rubber products such as conveyor belts, hoses, seals, and gaskets to improve strength and wear resistance. And it can be used in the production of concrete and other building materials. And it can act as a thickening agent.