Cable Beads

Cable Beads

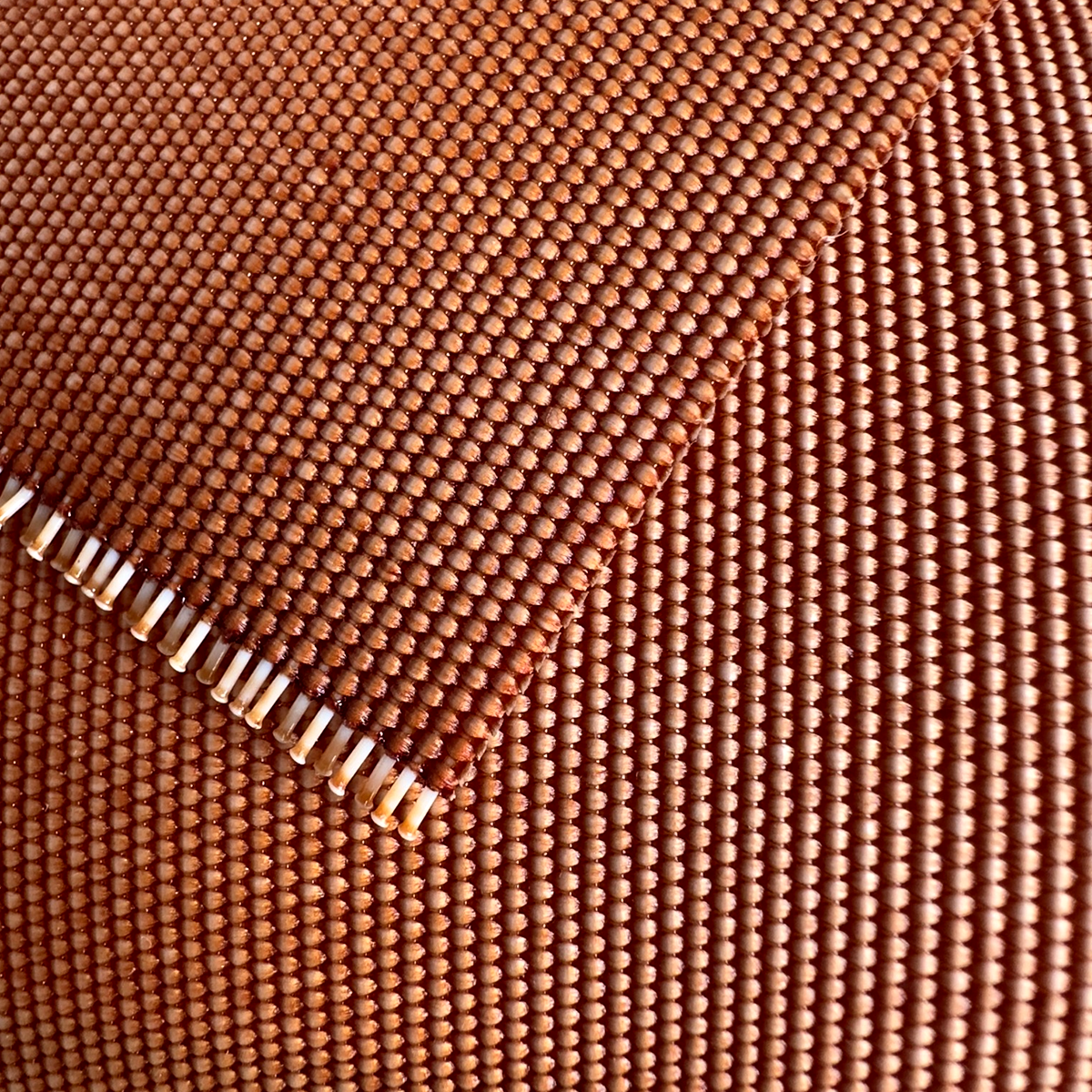

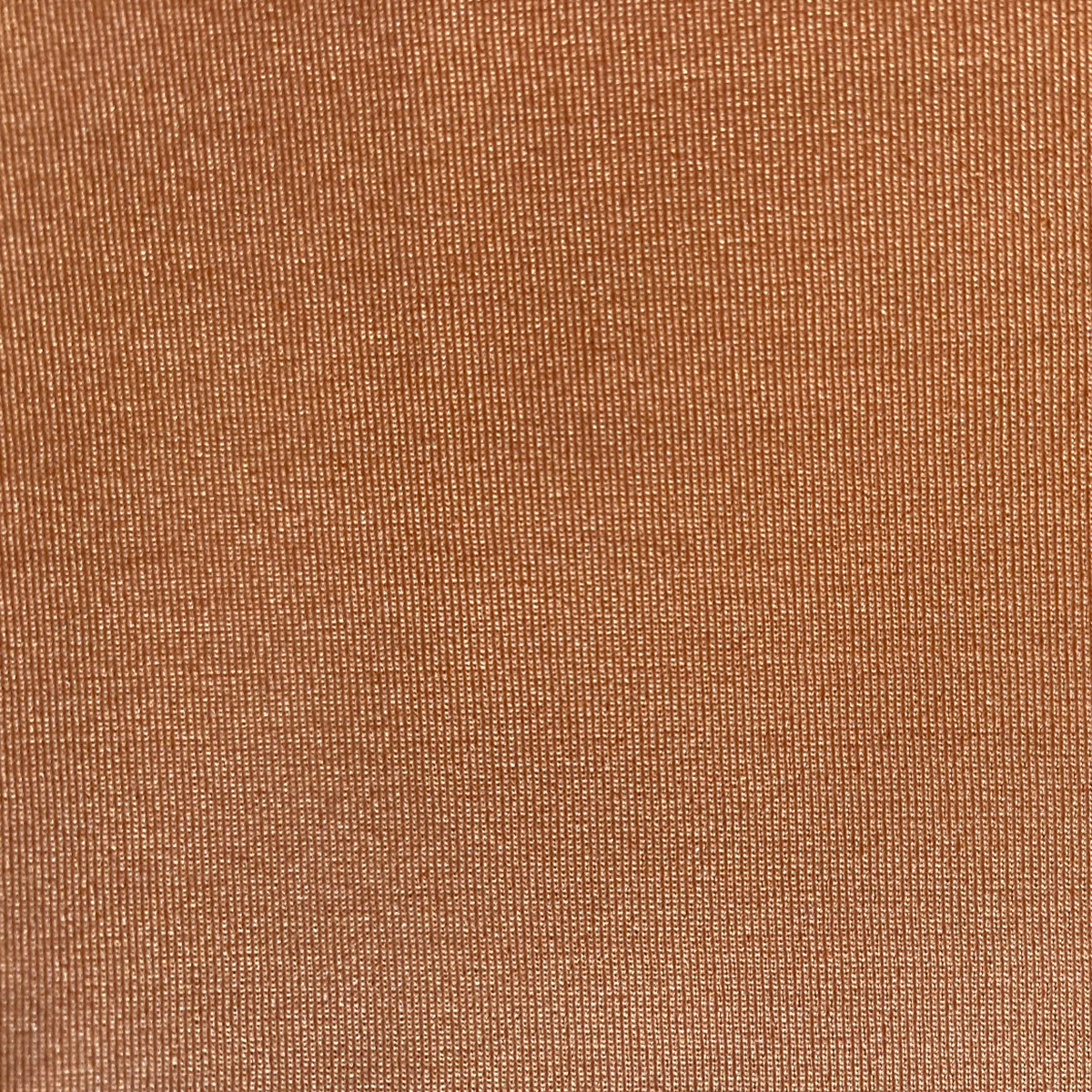

Cable bead adopts structure of cable with a core ringing the center; The outer layer is composed of multiplestrands of wire winded on the ring core, and the crosssection of bead is circular. The outer layer can be one or more, between the layers the direction of winding can be either the same or different.

Compared with the traditional structure of bead(suchas hexagon), cable bead has no sharp corners. As a result, It is not easy to form stress concentration or have a cutting effect on the carcass cord, which leads to a better performance in protecting the tire.

Category:- Advanced Materials

Description

Introduction:

Cable Bead Adopts Structure Of Cable With A Core Ringing The Center; The Outer Layer Is Composed Of Multiplestrands Of Wire Winded On The Ring Core, And The Crosssection Of Bead Is Circular. The Outer Layer Can Be One Or More, Between The Layers The Direction Of Winding Can Be Either The Same Or Different. Compared With The Traditional Structure Of Bead(such as Hexagon), Cable Bead Has No Sharp Corners. As A Result, It Is Not Easy To Form Stress Concentration Or Have A Cutting Effect On The Carcass Cord, Which Leads To A Better Performance In Protecting The Tire.

Product Construction:

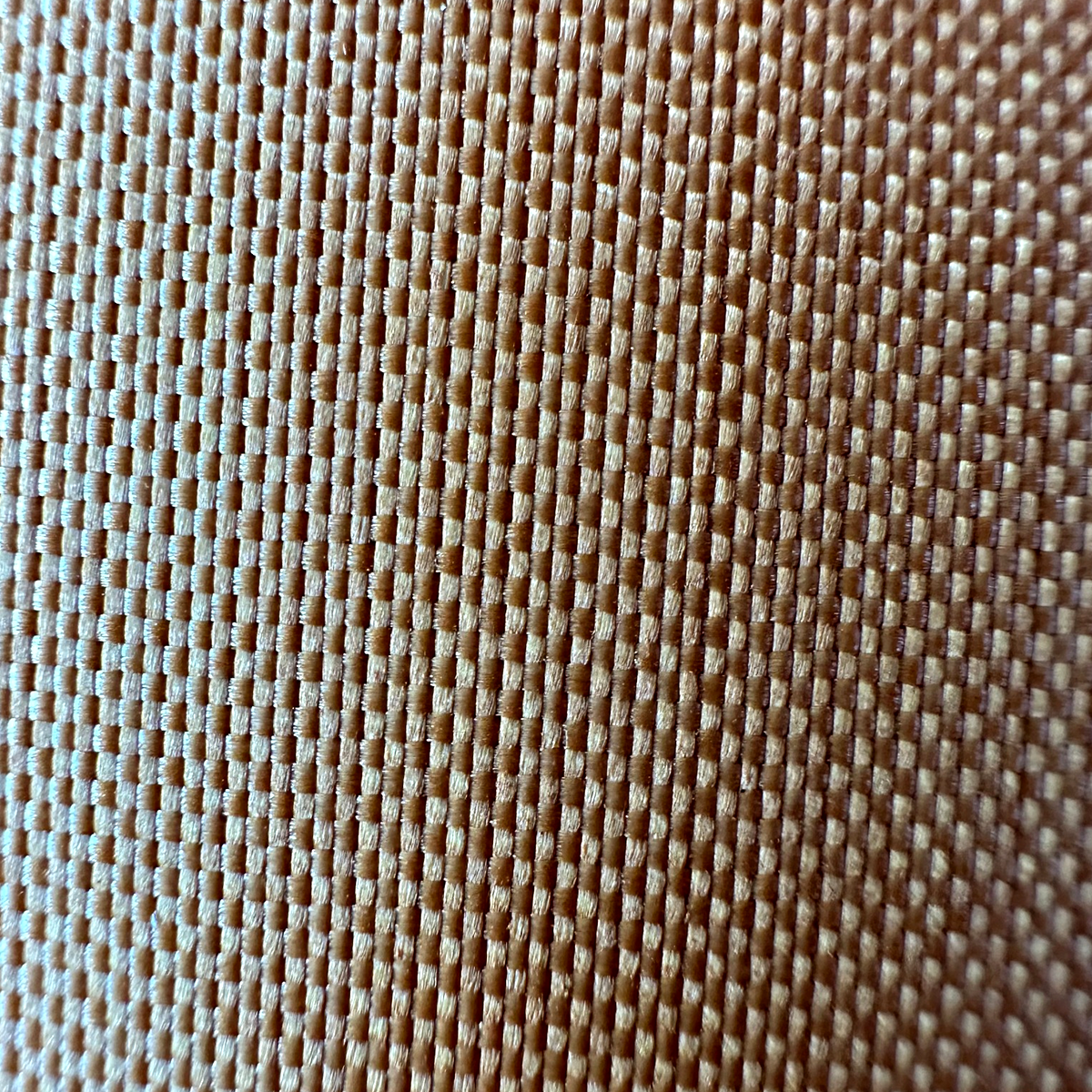

- The outer layer wire is justone single wire that fixed endto end by a sleeve/joint.

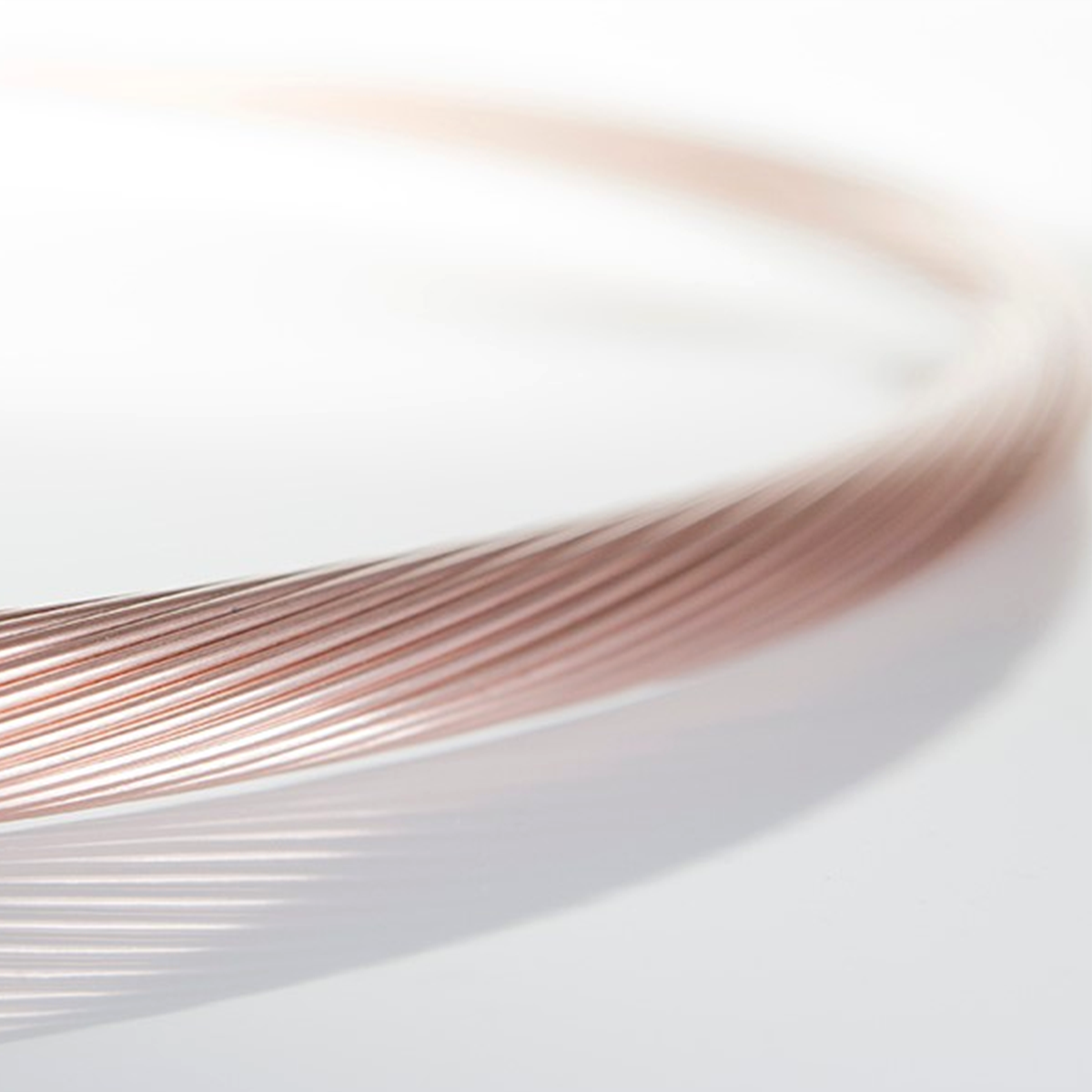

- Core Ring: No coating(can be coated if needed)

- Outer Layer Wire: Bronze coating

- (matching the original curing system)

Technical Specifications of Cable Beads

- Construction: Design On Customer Request;

- Cross Section Diameter: From 3 To 75 Mm;

- Minimum Breaking Load(KN): 7KN-2500KN Depend On Different Constructions;

- ID Of Cable Bead:from 66 To 2000 Mm ID

Advantage of cable Beads:

- The light weight — helps to lower the rolling resistance of the tire.

- High strength — the cable bead is about 20% lighter for the same tensile strength.

- Tire bead area strength is high – Less deformation after vulcanization.

- The uneven stress of hexagonal bead is solved.

- The stress of the bead in tire: the hexagonal bead has a larger deformation ratio and stress value than cable bead.

Main application of cable Beads:

- Aircraft tires&Aero tires

- Racing tires

- EV tires

- Air spring system

Related products