Introduction:

YUSHENG has experiences in producing green ethylene using ethanol extracted from sugarcane as raw materials, coupled with Lummus and its process and technology licensing capabilities, will lay a solid foundation for the development of this green alter- native, which uses carbon captured from sugarcane. Converting carbon from the atmosphere into plastics and other chemical products can help combat climate change the market application advantages of bio-based PE mainly lie in environmental protection. According to data provided by Braskem, the world’s largest bio-based PE production company, every ton of bio-based PE produced can capture 2.5 tons of carbon dioxide from the atmosphere, achieving carbon reduction.

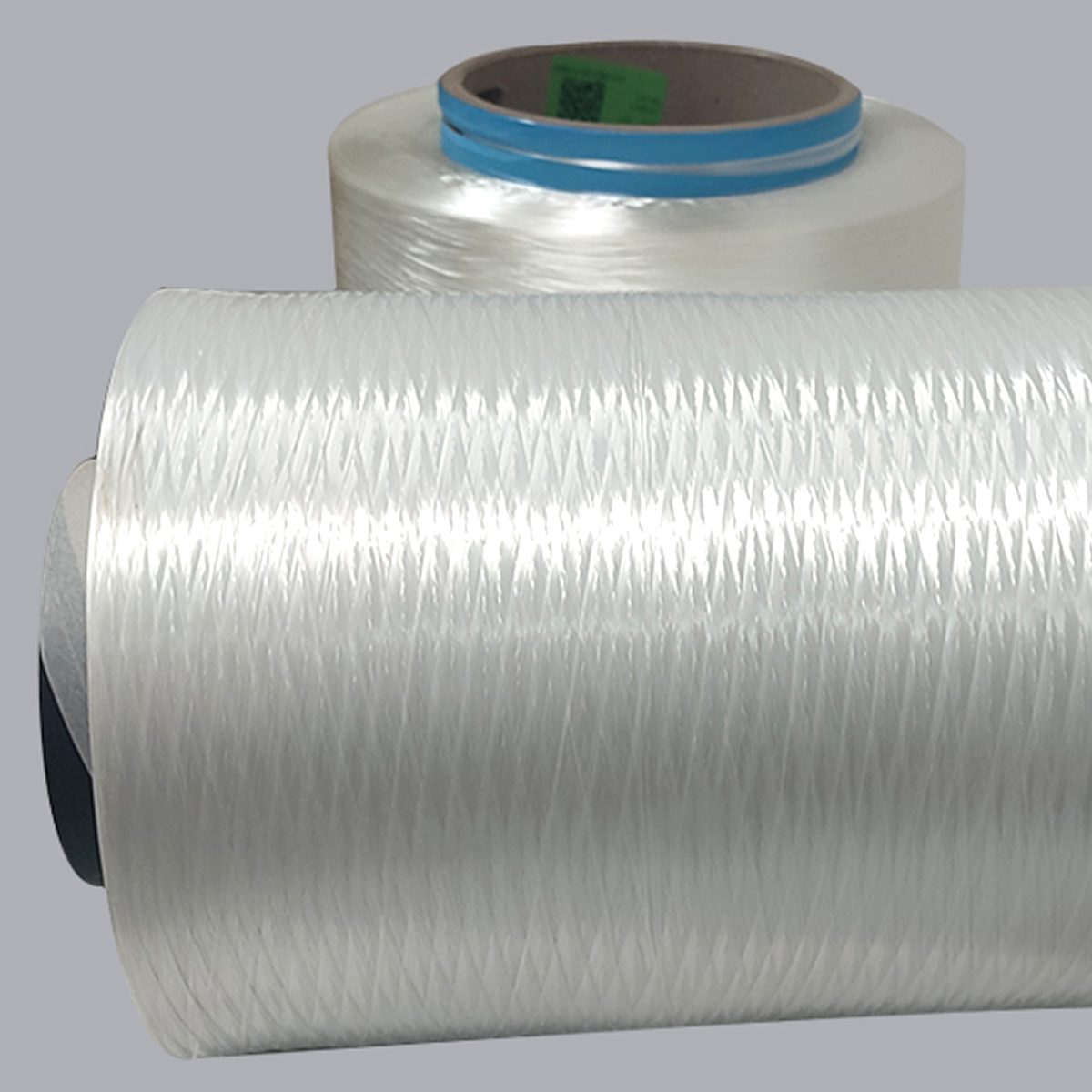

Specification:

| Item | 210D | 300D | 420D |

|---|---|---|---|

| FLAMENT | 36F/48F | 48F/72F/144F | 48F/72F/144F |

| LINEAR DENSITY DEVVIATION | ±3% | ±3% | ±3% |

| LBREAKING TENACITY CN/DTEX | ≤4.0 | ≤4.0 | ≤4.0 |

| ELONGATION AT BREAK | ≤30 | ≤30 | ≤30 |

| HOT AIR SHRINKAGE (132°C×0.05cn/dtex) | ≤10 | ≤10 | ≤10 |

| COLOUR FASTNESS | 4-5 | 4-5 | 4-5 |

Application:

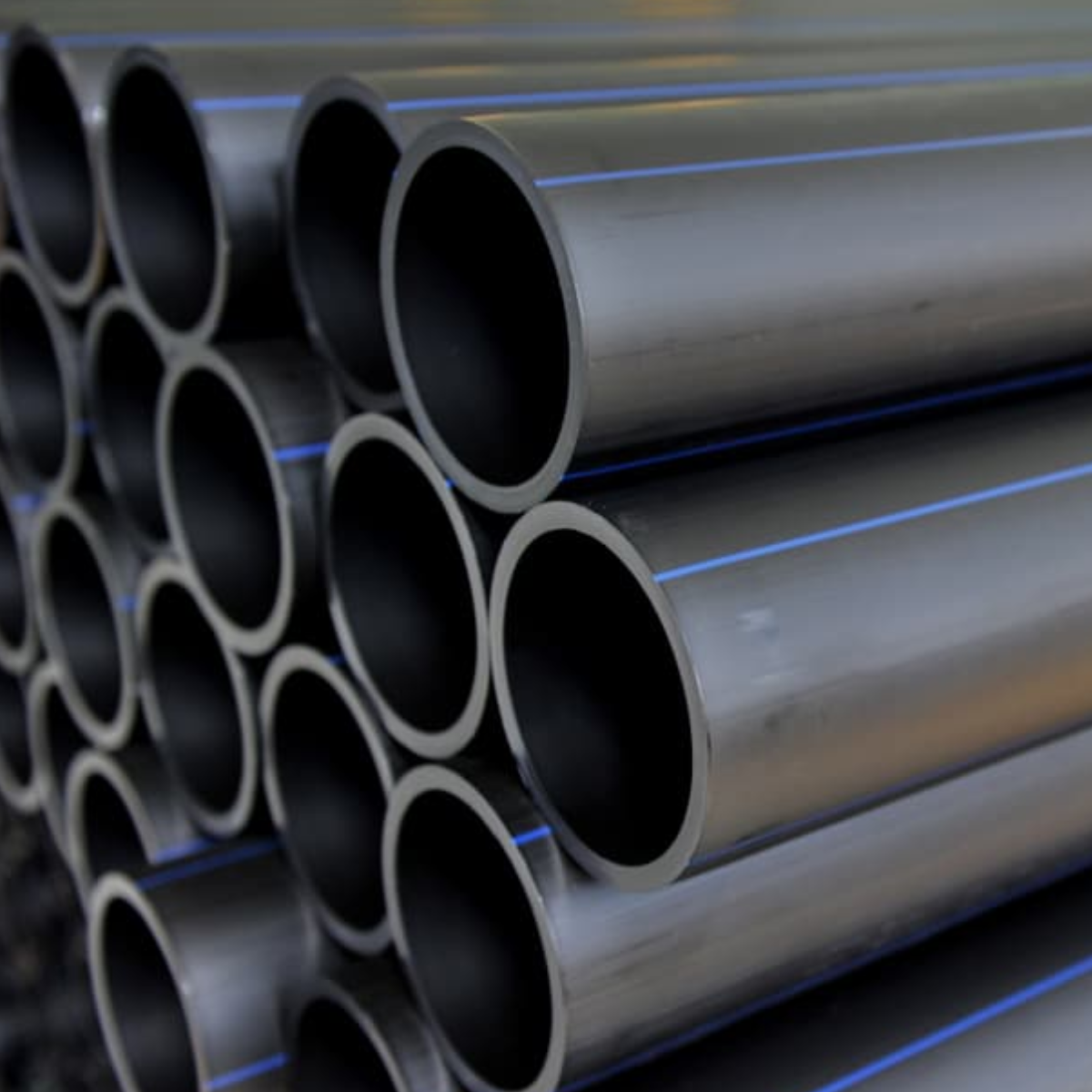

Green Sugarcane PE Yarns are used in the production of various packaging materials, plastic bags, food packaging, industrial wrapping, mulching films, greenhouse films, crop protection, some automotive components, pipes, sheets, some medical devices and packaging, etc.