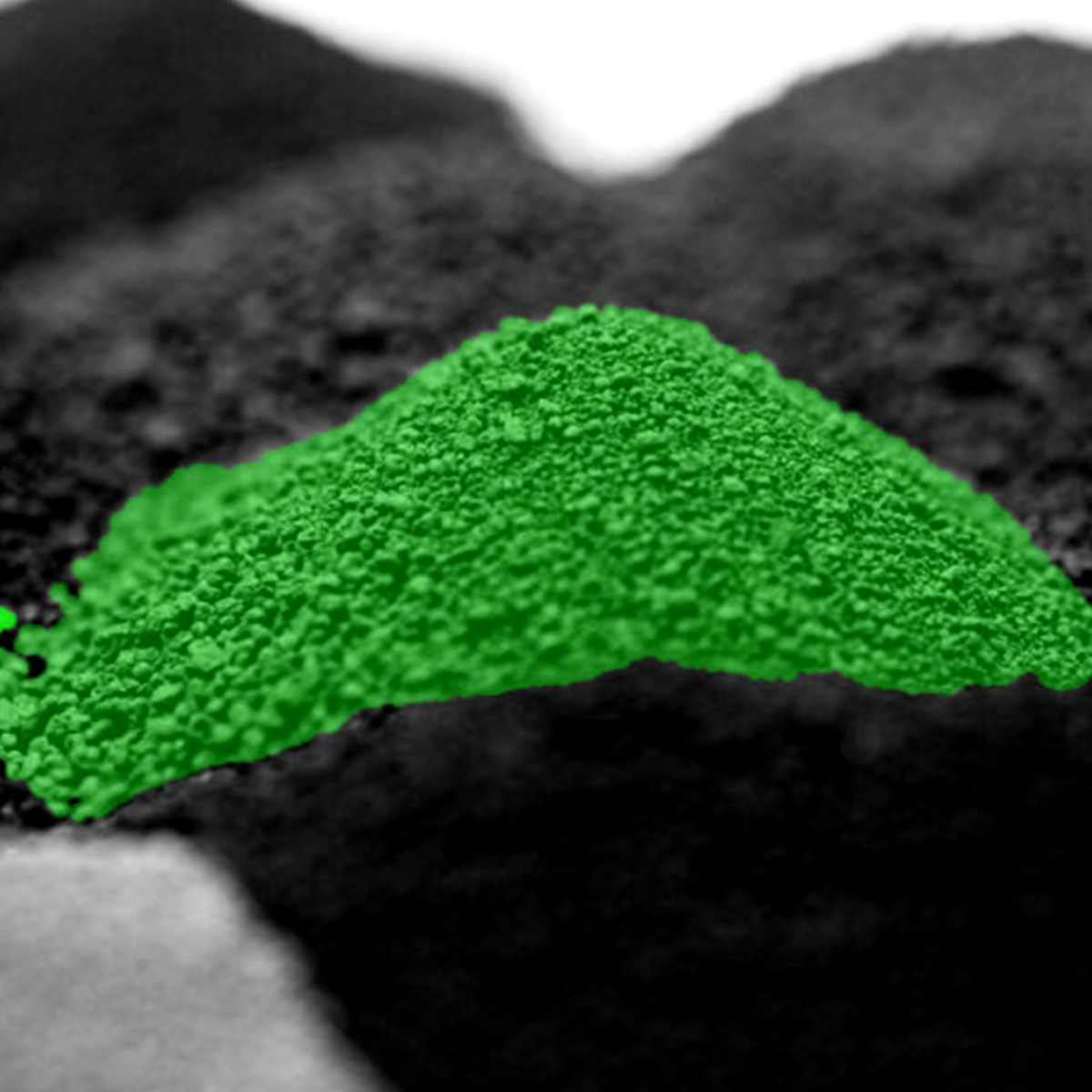

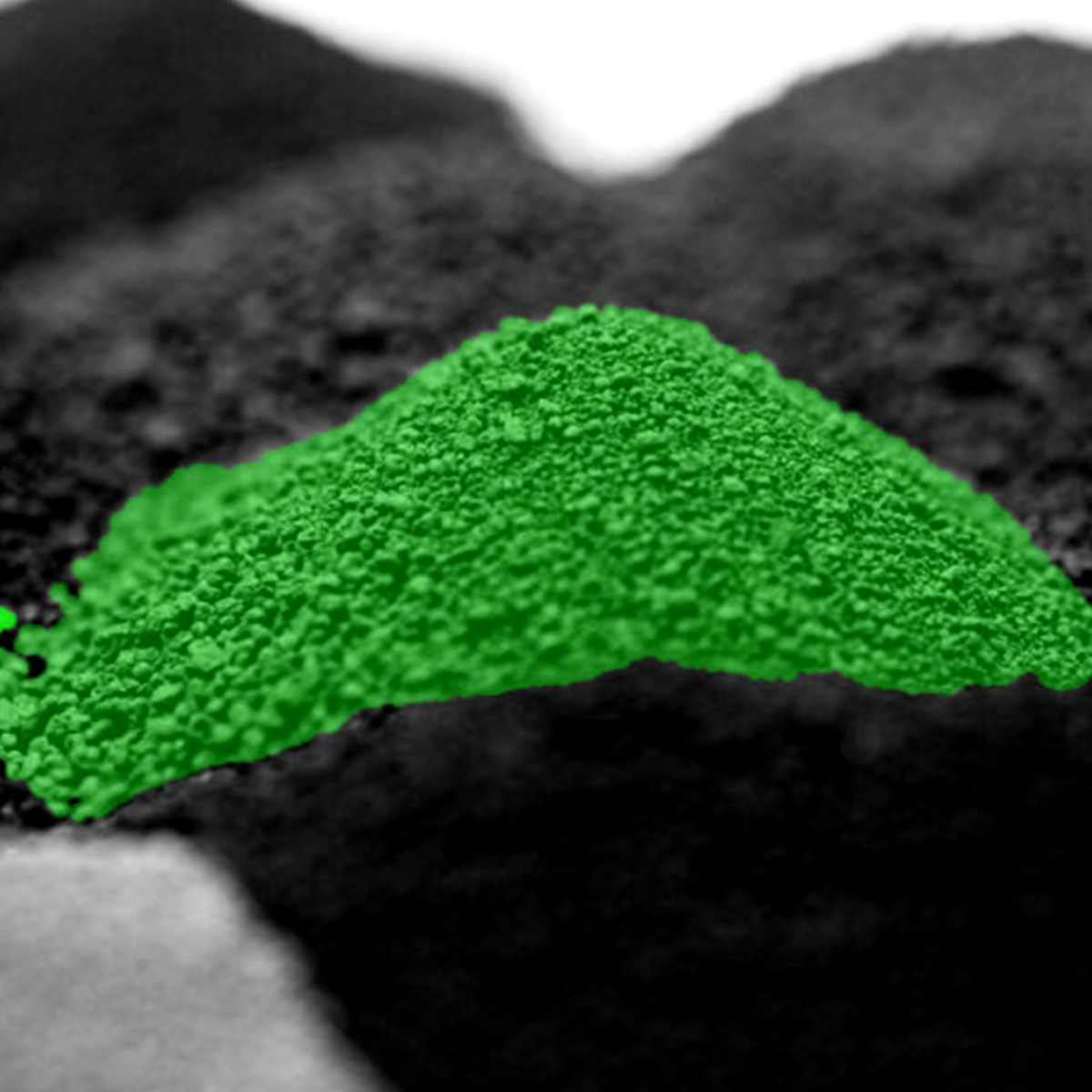

Green Carbon black

Green Carbon black

Introduction:

Green carbon black, also known as biochar, is a form of carbon produced from biomass through a process called pyrolysis, within the production process the polycyclic aromatic hydrocarbons (PAHs) of the virgin carbon black material are effectively ‘cleaned’ off the material to a concentration of <5 ppm.

Category:- Eco-Friendly Carbon Black

Description

Specification:

| Specification | Basic properties of carbon black |

|---|---|

| GLP220/BLP220/ULP220 | Basic performance is comparable to the N220 |

| GLP330/BLP330/ULP330 | Basic performance is comparable to the N330 |

| GLP550/BLP550/ULP550 | Basic performance is comparable to the N550 |

| GLP660/BLP660/ULP660 | Basic performance is comparable to the N660 |

| GLP774/BLP774/ULP774 | Basic performance is comparable to the N774 |

Standard Sales Specification

| PAH CONTENT | TEST METHOD | Unit | STANDARD | ||

|---|---|---|---|---|---|

| GLP series | BLP series | ULP series | |||

| Benzo(a)pyrene | internal testing | PPM | ≤1 | ≤0.05 | ≤0.2 |

| For each of 8 PAH included in EU list | internal testing | PPM | ≤1 | ≤0.05 | ≤0.2 |

| For sum of 15 PAH included in GSMark list | internal testing | PPM | ≤50 | ≤10 | ≤1 |

Application:

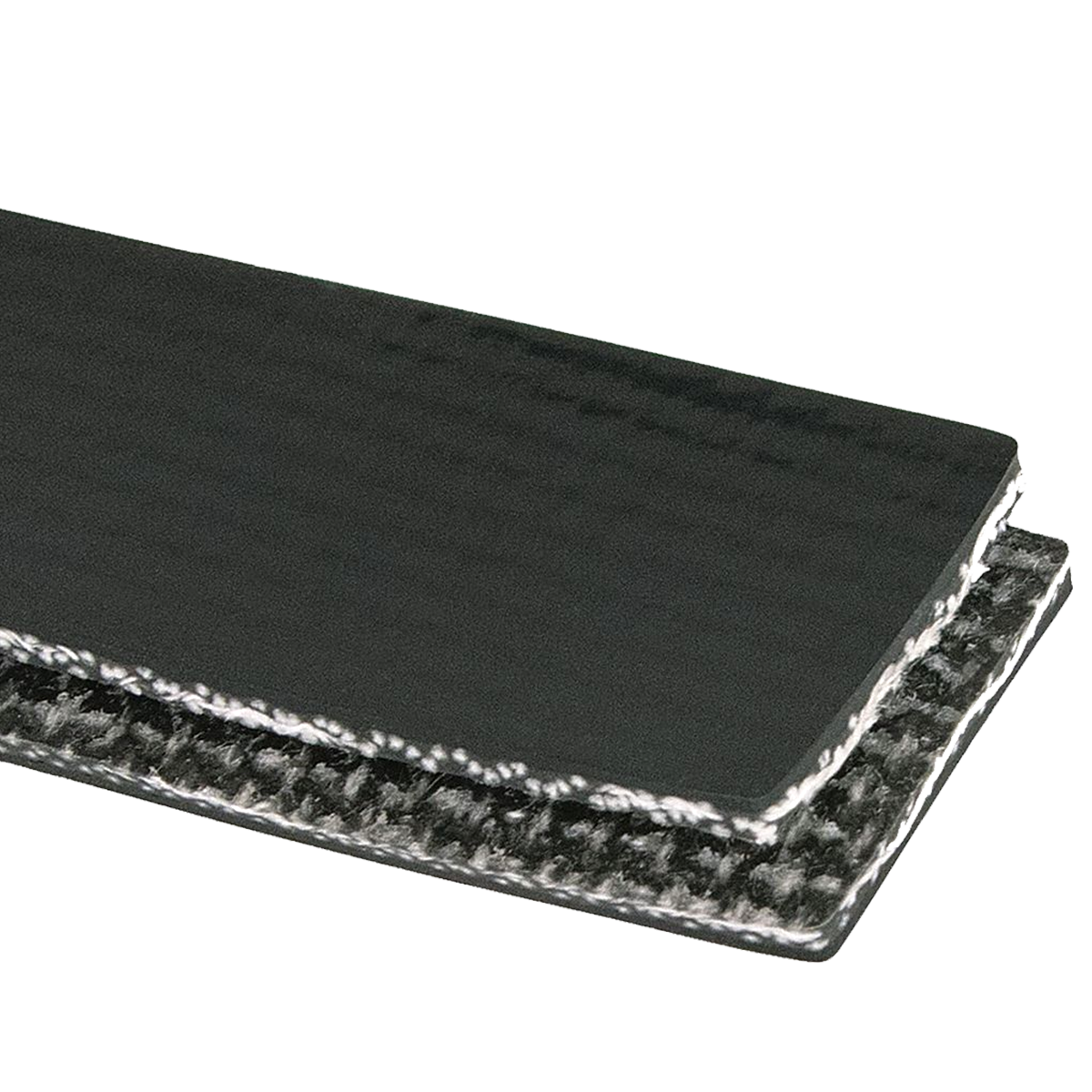

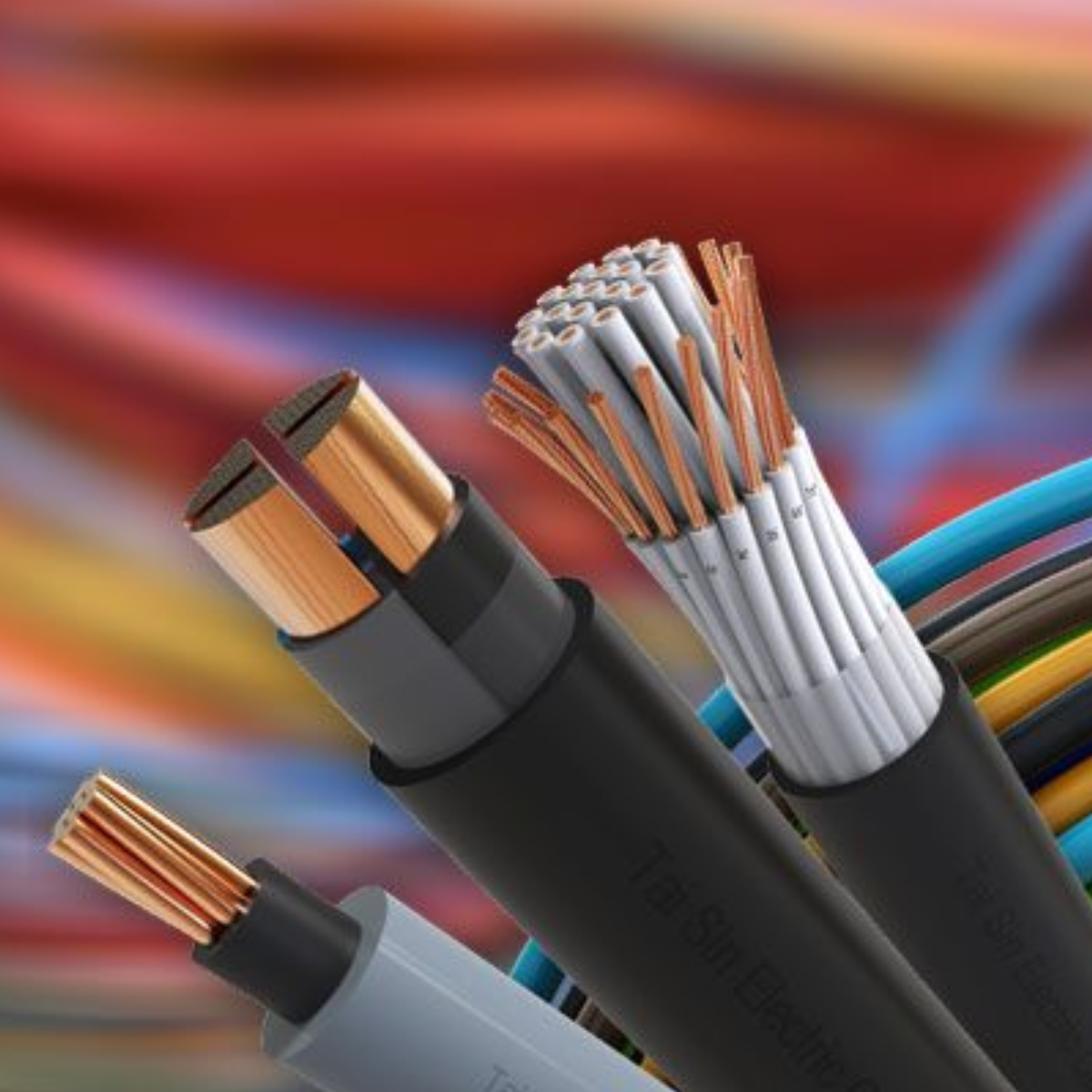

Green carbon black reinforces rubber in tire manufacturing, enhancing strength. In cable insulation it can provide enhanced conductivity and mechanical strength, and its use in components like conveyor belt and rubber hoses, and improving durability and weather resistance in construction adhesives.

Related products